It is known that effective work engine timing largely depends on the optimal characteristics of the ignition timing. If the angle is too late, throttle response decreases, fuel consumption increases, and the engine begins to overheat. If the angle is too early, detonation occurs, resulting in a loss of power and the risk of burnt valves. Modern systems engine controls strive to maintain as large an angle as possible, but without the characteristics “going” into the detonation zone. The knock sensor (hereinafter referred to as DD) informs the control system about the onset of detonation, and the latter corrects the characteristic based on this data.

There are two types of DDs: resonant and broadband. Wideband captures and transmits the entire spectrum of noise as a signal. Next, the signal is processed and noise is separated out, respectively. detonation. Resonant ones are tuned to the detonation frequency, and accordingly. are triggered only if the latter occurs. VQ engines use a resonant type DD.

Under normal operating conditions (normal gasoline, serviceable spark plugs, etc.), the control unit uses tabular characteristics which are considered optimal. In other words, the DD circuit is not used under normal conditions. However, if for some reason detonation begins, the DD sends a signal to the control unit, which adjusts the ignition characteristic towards a decrease in the advance angle. If detonation does not stop, the unit adjusts the characteristic again, etc. in a cycle until detonation stops. This achieves optimal performance for these specific operating conditions. This simple algorithm is called closed loop and is used by engine management systems to regulate many important parameters, such as the composition of the air-fuel mixture, etc.

From all of the above, the conclusion follows that under normal operating conditions, the DD does not seem to be needed. But it is not so. Firstly, in our conditions you can never be sure of the gasoline that is poured into the tank. In addition, detonation can occur under many other conditions: problems with spark plugs, compression, etc. Secondly, it is not known exactly how the control unit behaves in the event of a motor failure. There is a suspicion that in this case it will switch to some “emergency” characteristic in order to be guaranteed to avoid detonation. This characteristic may be far from optimal, and accordingly lead to an increase in fuel consumption, a drop in throttle response, etc. As soon as there is accurate information on this issue, it will be possible to say unambiguously how much DD is really needed.

How to check the serviceability of the knock sensor

You can check the sensor yourself in a few minutes using the self-diagnosis system. Here is a detailed description of how this is done. If code 34 is displayed, this indicates a sensor failure. You can find out whether the sensor has “died” completely or is still trying to work. To do this, you need to reset the self-diagnosis result, drive a couple of kilometers and repeat the checking procedure. If the code appears again, it means the sensor is not working at all. If not, then you can try to delay the time before replacement by registering the control unit with the help of Consult at a proprietary service.

How can I replace the knock sensor?

Obviously a different sensor. Possible options: a suitable sensor from other engines (for example, from injection VAZs); new original; new non-original; original used.

Regarding the sensors from injection VAZs. Based on the theory, which is confirmed by practice, it is not worth wasting time looking for a “suitable” sensor from injection VAZs. VAZs use two types of sensors: broadband two-contact 2112-3855020 and resonant single-contact 2112-3855010. Obviously, a wideband sensor will not work on Cefiro. As for the resonant one, there is also a problem here: the resonant frequency of detonation may differ (although there is no certainty about this). Accordingly, the sensor will either not work at all, or (which is much worse) will work incorrectly. It should also be added that, according to available information, Russia does not yet produce resonant sensors for VAZ, only broadband ones. So, if you’re going to look for an analogue, then it’s among imported products.

A new original sensor on Cefiro costs $100-150 depending on the region and supplier, plus 10-14 days for delivery. A used one costs an order of magnitude cheaper and can be bought at some sort, but there is no guarantee that you are not changing the “stuff for soap”. As for non-original sensors, it is better to look for products from a well-known manufacturer.

Replacement procedure

The sensor is located on the left side of the engine (in the direction of travel, i.e. on the side where it is located air filter), between the halves of the cylinder block. The sensor is attached with a 12mm bolt. It is possible to get to it, but it is quite difficult. It is easier to do this operation in an authorized service. It will take 10-20 minutes.

We are talking about a device designed to respond to the appearance of detonation in the engine. When such a process occurs, the sensor sends an electrical impulse to the car control unit, which automatic mode adjusts the ignition timing, which leads to the cessation of detonation.

By appearance This is a monolithic structure with a piezoelectric element located inside the housing. The knock sensor (or DD) is mounted on an engine equipped with electronic system fuel injection (injector). This device registers the fact of detonation and sends the received data to the computer ( the electronic unit management). The received information is processed by a computer and issues a command to adjust the ignition angle: as a result, detonation, which negatively affects the functioning of the engine, is avoided.

Why does detonation occur?

Here we can distinguish three main reasons due to which the engine begins to operate unstably:

- octane number fuel: the higher it is, the less likely it is that this unpleasant phenomenon will occur (the quality of the fuel is also important);

- design features of the engine: units with a high compression ratio are more prone to detonation, and therefore they must use fuel with an octane rating no less than that specified in the instructions;

- engine operating conditions: incorrectly selected gear, excessive load on the engine, incorrect composition of the working mixture - all this also leads to detonation.

Where is the DD located?

On the engine block between the 3rd and 2nd cylinders. This choice is not accidental: this is the hottest place in the engine and the shortest distance to two cylinders at the same time. The location where the sensor is fixed must be level to eliminate acoustic resistance.

Operating principle of the knock sensor

Essentially, this is a non-separable round housing that has a hole for fixing on the cylinder block, as well as terminals used for connecting to on-board network car. The main part of the sensor is a piezoelectric element located inside and generating small electrical impulses when subjected to mechanical action. When detonation occurs, sound waves with a frequency of 25-75 Hz are formed. They spread throughout the cylinder block and reach the piezocrystal, causing it to vibrate in unison with the “arriving” sound. Moreover, the greater the amplitude, the stronger the generated voltage. The generated pulses enter the on-board computer.

Sensor types

There are two versions of the device. The first of them is broadband. It is characterized by the fact that it simultaneously perceives several frequencies, on the basis of which it forms a voltage level transmitted to the ECU. The second type of sensor is tuned strictly to a specific frequency. Such a DD generates an electrical signal when a resonance coincides (or occurs) with acoustic waves generated by detonation in the air-fuel mixture, when the latter has already ignited.

Knock sensor malfunctions and their symptoms

The DD ECU may not respond for a number of reasons. The first sign is the Check light on the instrument panel coming on. However, it will not necessarily glow constantly: it may ignite briefly when high loads. However, Check can also signal in case of other engine malfunctions. The second sign is loss of power, accompanied by increased consumption fuel. However, the situation is the same here: similar symptoms can also appear with other faulty engine elements. But the best thing to do is to move on to testing the sensor itself.

In most cases, one of the three methods described below is used.

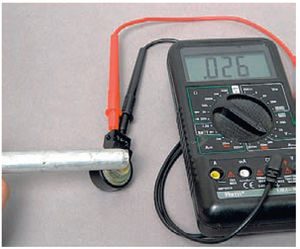

- You will need a tester to measure the resistance of the DD. Set the measurement limit on the multimeter to 2 kOhm and connect the probes of the device to the terminals of the knock sensor. In a calm state, the tester will show “0”. Now take, for example, a wrench and lightly tap the DD body. If the multimeter needle deviates, indicating an increase in resistance, then the sensor is working. The lack of reaction from the tester indicates that the piezoelectric element inside the DD is not functioning and you need to buy a new part.

- You can also use a voltmeter. It is necessary to set the voltage measurement limit to 200 mV. Connect the negative probe of the multimeter to ground and the positive probe to the sensor terminal. Tap lightly on the DD: if the part is serviceable, then a voltage of approximately 10-15 mV should be displayed.

- This method is simpler, but allows for more accurate diagnosis. Start the engine, setting the crankshaft speed on the tachometer within 1500-2000 rpm. In this case, the engine must be warmed up and run steadily. Find the location of your knock sensor and lightly tap it with the same wrench. If the DD is working, then it will send a voltage pulse to the ECU, which, having received the command, will adjust the ignition angle. This can be determined by ear by a decrease in engine speed. If you stop influencing the sensor, the speed will be restored to the initial value.

- Take a known good DD and install it on your car.

Other ways to check the functionality of the DD

Accelerate the car to a speed of 30-35 km/h, engage a higher gear and sharply press the accelerator pedal. If the sensor is working properly, then you will hear detonation knocks, which will disappear very quickly, because the electronics will come into play and change the ignition timing. The absence of detonation serves indirect sign DD malfunctions. Additional symptoms of sensor failure include:

- overheating of the motor at relatively low ambient temperatures;

- engine “triple” (glow ignition);

- the appearance of carbon deposits on the spark plugs, which is caused by an excessively rich fuel-air mixture.

Replacing DD

First, remove the positive terminal from the battery and disconnect it from the DD electric wires. Now you need to unscrew the nut with a “22” wrench (you may need a “13” wrench - it all depends on the DD model) and remove the part. Installation must be done in reverse order. At the same time, check that seat it was clean. Tightening force (if you have a torque wrench) – 10-25 N*m.

One of the desired responsibilities modern driver– know how to check the knock sensor and what it affects. However, it won’t hurt anyone to educate themselves about the other sensors either. For there are often cases when the dashboard begins to flicker like a Christmas tree, and the owner of the car falls into either complete ignorance or the wildest panic.

Without a doubt, the electronicization of the car has made it easier to communicate with him, and has greatly simplified control over his health. But without at least initial theoretical knowledge and practical skills, the entire filling turns into a set of meaningless and uninformative details.

Yes, there are so many car services now that you can find them even in a half-forgotten outback. But if the console blinks, you need to know how seriously you are in trouble: will you get to the nearest service station, albeit slowly, slowly, or should you ask a passing vehicle for a tow. After all, a breakdown may not be too dangerous, allowing you to drive another 300-500 kilometers, or even more, but it can be so painful that without urgent and close attention, restoring the car will cost a lot of money.

How to check the knock sensor and what it affects We will tell you what its functions are in this material. We will try to make it detailed, but not boring and accessible.

Why do you need DD? Detonation is a phenomenon that is extremely dangerous for the engine. Persistent and increasing explosions in the combustion chamber can cause destruction of the cylinder block. Before the appearance electronic control the correction was carried out manually by turning the ignition distribution cap depending on the octane rating of the fuel.

On modern engines it is fixed motionless, and the adjustment function is taken over by the ECU, focusing on the data received from the DD. Its main component is a piezoelectric plate, at the spaced ends of which voltage appears during microexplosions. Exceeding a certain threshold results in a signal from the ECU.

What are the risks of DD failure?

Let us immediately console the unenlightened: if the sensor fails, you can drive a car, and you don’t even need to be too careful. However, when it stops receiving data from the sensor, the ECU accepts preventive measures and sets the ignition retard. This has some consequences:

- fuel consumption increases noticeably and can reach 15-20%;

- engine power drops; under increased loads (for example, moving uphill with a load), you have to add speed to row out. Consequences: overheating and faster wear;

- You can no longer expect the usual agility. You will accelerate like on an old “penny”; overtaking a truck, for example, will become difficult;

- a smoky exhaust will appear, which is an additional inconvenience: you will not be able to understand that problems have begun that are accompanied by a similar symptom.

DD check

The most reliable check is, of course, scanning with a professional tool. However, before visiting a service station, you need to make sure that it is the one that is failing. caught fire warning lamp is not at all a 100% indication that it was the one that failed.

Contacts may oxidize, wiring may be interrupted - there are hundreds of reasons for the appearance of an alarm light. And we note that no one will scan you for free. Therefore, it is better to find out for sure that the problem is caused by it, so as not to waste money. For a simple test, you only need a sensitive voltmeter.

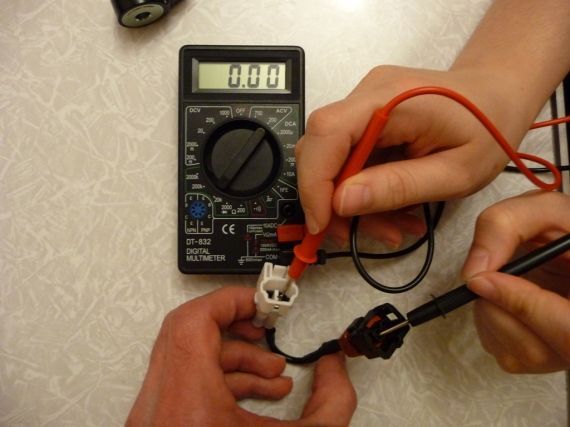

- The knock sensor is removed from the vehicle;

- The measuring device is switched to millivolt measurement mode - otherwise an indicative picture will not work.

The positive of the voltmeter (usually marked in red) is connected to the signal wire of the sensor; - The minus, black, is connected to the DD ground (the bolt passes through this place);

- Then you can hold the sensor in your fist and tap it on the table with different strengths, or you can lightly hit its body with the plastic handle of a screwdriver;

- The device must detect changing voltage. For different sensors, fluctuations can be 30-40 mV (the figure is previously clarified using the attached manual or other technical documentation). If there are no changes, the sensor should without any doubt be replaced.

The knock sensor (DS) transmits a knock signal to the electronic control unit (ECU). The response of the ECU is to reduce the ignition timing and enrich the engine fuel-air mixture. Essentially, the knock sensor is responsible for early detection of detonation of the mixture. Now you know what a knock sensor is needed for.

Detonation in the engine - These are explosions of the fuel-air mixture. Reasons for this gasoline engine maybe several. Here are some of them:

- low octane fuel;

- lean fuel-air mixture;

- ignition too early;

- a thick layer of carbon deposits in the combustion chambers, increasing the compression ratio of the engine.

The consequences of prolonged exposure to this process on the engine are most often broken partitions between the ring grooves on the pistons. This, in turn, leads to a drop in compression and the formation of scoring on the cylinder bore. These malfunctions are eliminated by repairing the cylinder-piston group of the engine, that is, boring and honing the cylinders, as well as replacing pistons and rings. From this it becomes clear why dampen detonation.

The presence of detonation in the engine can be determined by the characteristic rattling metallic sounds, which many drivers confuse with the knocking of fingers in the connecting rod.

Operating principle

The operation of the device is based on the property of plates made of materials called piezoelectrics to convert the mechanical energy of pressure applied to them into the potential difference of their opposite sides. Such a sensor consists of a housing with fastening elements to the engine, and a piezoelectric plate inside with terminals connected to its opposite ends. The plate is deformed under the influence of sound vibrations during detonation and converts the energy of mechanical vibrations into electrical impulses of the appropriate frequency and amplitude. Malfunctions are most often associated with broken leads inside the housing. Despite the apparent simplicity of the defect, no one tries to repair the sensor, preferring replacement rather than repair.

Varieties

The knock sensor can be either resonant (in the form of a cylinder with one contact on top), or broadband (looks like a thick washer with a two-pin connector).

The wideband knock sensor converts all engine noise into electrical vibrations and transmits them to the ECU for recognition and decision-making.

The resonant one is tuned to the engine detonation frequency and produces a signal only when the noise frequency matches its resonant frequency.

Please note that wideband sensors are not interchangeable with resonant sensors, even if they are made by the same company.

Knock sensor design (Mazda 3)

Signs of a DD defect

Symptoms of malfunction:

- high fuel consumption;

- periodically occurring detonation;

- turning on the indicator " check engine» on the instrument panel;

- poor pickup;

- reduction in engine power;

- increased exhaust smoke.

It would be appropriate to check the knock sensor if any of these signs appear, especially the second one. We'll talk about how to check the knock sensor below.

Verification methods

Motor resonance calculation

If your car's engine is equipped with a resonant sensor that has failed. And for some reason you want to replace it with a sensor of another model, then for this you need to know the resonant frequency of your engine. It can be calculated using the empirical formula:

F res = 900/(π * r), where π - 3.14... r is the radius of the piston in millimeters, the result will be in kHz.

For example, for power unit with a piston diameter of 82 mm F res = 900/(3.14 * 41) = 6.99083 kHz or after rounding 6.991 kHz.

To replace, you need to select a sensor with a resonant frequency as close as possible to the engine resonance frequency. After the sensor is selected, you need to adjust its electrical resistance to the value of the “native” sensor. If the resistance of the new one is much higher, solder a resistor in parallel with it with the same resistance as the old one. If the resistance of the new one is lower, then solder a resistor in series with it with a value equal to the difference between the resistances of the old and new ones.

Checking the knock sensor can be carried out in several ways, namely by checking the resistance of the DD and the change in its voltage when exposed to a metal object on the sensor.

The easiest way, of course, is to connect the scanner to a computer and read all the engine parameters, including the DD signal curve. But for those car owners who do not have this opportunity optimal method will be measured by the tester.

In this case, we will analyze in detail how to check knock sensor engine in voltage mode, and we will also describe in detail how to check the DD for changes in resistance.

First of all, before checking the functionality of the knock sensor, it would not hurt to familiarize yourself with the theory of what it is and how it works. When detonation occurs in the engine, a shock wave passes through, shaking the sensor, in which a potential difference of several millivolts arises. In addition, the electrical circuit of the DD has its own internal resistance. This resistance differs depending on the brand and model of the sensor.

Both when measuring resistance and when measuring voltage (by applying a metal object to the sensor) - the procedure is performed on a removed sensor.

Checking the knock sensor for resistance

We remove the sensor, take a multimeter, set it to the “kOhm resistance” measurement mode and knock on the iron casing of the motor with a metal object (simulating engine detonation) and look at the changes.

Checking the voltage change of the knock sensor

We switch the tester to the “milivolt” mode, connect the positive probe to positive contact, and negative to sensor ground. And simulating a detonation shock wave, we look at the potential difference (about 30-40 mV depending on the intensity). A multimeter will show you how the sensor converts detonation into alternating current. Which indicates the serviceability or malfunction of the knock sensor.