Modern car embodies a bundle of engineering thought. Each unit in it is equipped with sensors that read information and send it to the electronic unit management. The ECU controls all car systems, thereby ensuring its smooth and efficient operation.

Sensors monitor the temperature of the coolant, engine oil pressure, throttle position, the amount of air supplied to the engine combustion chambers and many other parameters of the vehicle's operating systems. The performance of the car depends on the serviceability of these small devices.

Among the sensors, the serviceability of which motorists should pay close attention to, the mass air flow sensor occupies a special place. What is a DMRV? MAF is a mass air flow sensor (in English terminology Mass Air Flow Sensor or MAF), the purpose of which is to determine the amount of air entering the engine. It is used on vehicles with fuel injection and can be used in conjunction with sensors that detect air temperature and atmospheric pressure.

Why do you need a mass air flow sensor?

The photo shows the mass air flow sensor. She's always on the way out air filter

As already mentioned, the main task of the mass air flow sensor is to inform about how much air is in this moment passes into the combustion chambers of the car's power unit. This information is important because, unlike carburetor engine, the working mixture in which is created by the carburetor, the injection engine forms the mixture in the cylinders. The air in the injector is sucked into the cylinders by vacuum, and gasoline is injected by injectors.

Each injection is strictly dosed, and the supply of fuel is controlled electronically based on information received from the sensors. The fuel dose depends on the position of the crankshaft, the speed at which it rotates, the throttle position, and the amount of air entering the cylinders. The DMVR sensor helps the ECU balance the fuel mixture and thereby ensure optimal engine operation under given conditions.

How does the mass air flow sensor work?

Air as a component combustible mixture, enters the cylinders through the air filter through the pipe. The mass air flow sensor is mounted in the air filter housing and connected to the pipe. The connections are sealed, air leakage is not allowed, thanks to this the sensor can accurately determine the amount of air that comes out after cleaning with the filter and transmit information to the electronics unit.

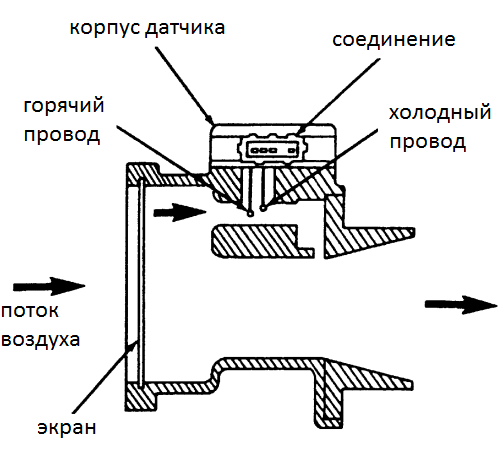

Internal structure of the mass air flow sensor used in the Ford Windstar

Mass air flow sensors installed on cars come in several types:

- The first sensors (air flow meters) were based on the principle of changing the resistance of a resistor under the influence of a bent plate. The blade plate is fixed in the flow meter body and bends under the air flow - the more powerful the flow, the greater the bend. The changing resistance of the resistor signals the car's control unit about the amount of air entering the engine.

- The most common flow meters today are based on the operation of hot-wire meters. Two thin platinum threads are built into the sensor body: one is working, and the other is control. Both threads are heated by current and have the same temperature. The working thread is blown by a stream of air and to maintain the temperature on it equal to the temperature on the control thread, the automation increases the current passing through the working thread. The difference in the current passing through the working thread determines the amount of air sucked in by the engine.

- In new generation air flow meters, silicon plates coated with platinum are used as meters.

Signs of a DMRV malfunction

Check engine - may indicate problems with the mass air flow sensor

Correct data from the mass air flow sensor provides the engine with constant effective mixture formation, and the slightest deviation in the operation of the device immediately affects the power and driving performance motor. A sensor failure may make it impossible to start the engine.

On a car may occur in the following situations:

- difficult to start the engine;

- The “Check engine” light came on;

- gasoline consumption has increased;

- the dynamics of speed gain have worsened;

- speed in mode idle move swim.

The same manifestations may indicate a breakdown of other devices on the car, so you need to contact a service station and conduct an inspection of the condition of the sensor.

How to check the mass air flow sensor

Disabling the mass air flow sensor

You can try to determine the malfunction of the mass air flow sensor yourself. There are several ways to carry out routine maintenance for this purpose.

- With the engine running, disconnect the block with wires from the sensor. The ECU will power the engine based on the readings coming from the throttle sensor. The engine speed will increase. Then you need to carry out a test drive - improvement in the performance of the power unit will indicate a malfunction of the mass air flow sensor.

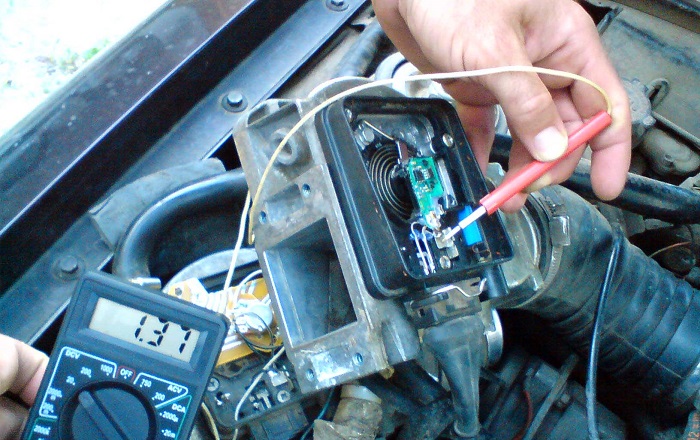

- Using a voltmeter, check the voltage between the “sensor signal” and “ground” wires. With the ignition on (the engine is not running), the voltage on the voltmeter should be in the range of 0.9-1.4 volts. Increased voltage indicates a problem sensor.

- You can try to clean the insides of the sensor from dirt by using an aerosol for this purpose, which is used to wash the carburetor.

Modern flow meters are complex and unrepairable devices, so you won’t be able to fix them yourself if they break down. Correct operation of the engine can be restored if the mass air flow sensor is damaged only by replacing it.

On domestic cars it is very common cause trip to the service station is the mass air flow sensor. This device is often located near the air filter and is responsible for the amount of air that enters the power unit. By measuring the amount of air, the sensor determines whether the engine has any problems, and also monitors the quality of the combustion chamber and the enrichment process fuel mixture. Not only engine power, but also safety in its operation depends on these important aspects. It often happens that it is the mass air flow sensor that becomes the most important issue in the car, which spoils the quality of the trip.

Many drivers of cars of the VAZ 2110 family have encountered problems with this unit. Today, most owners of these cars know how to check the mass air flow sensor and adjust its normal operation or replace it with a new one. If you have more modern car, it is not recommended to check and change the sensor yourself. It is better to have the work done at a specialized station and get a guarantee for high quality your suggestions.

What are the first symptoms of a MAF failure?

The mass air flow sensor not only measures, but also controls the flow of air into the engine. Everyone's work technical parts cars drive computer systems, which in most cases are controlled automatically. This is why the work of the mass air flow sensor is so important. It affects the quality of operation of the power unit and its suitable operating modes. Such important roles in vehicle make the sensor a real problem if it breaks.

The main features of sensor failure can be described by a list of several symptoms of problems. But it is also worth considering that in some cases it is impossible to determine the origin of the symptoms of a problem on your own. Sometimes it's easier to pay for high-quality diagnostics than to look for the causes of a particular problem on your own. Among the typical features of a mass air flow sensor failure, the following behavior patterns can be identified:

- on dashboard the cherished light bulb lights up Check Engine and requires you to perform engine diagnostics;

- gasoline consumption increases, and the increase may be quite high and unpleasant;

- when stopping near a store for a few minutes, starting the car becomes a real problem;

- the dynamics of the car decrease, acceleration becomes slower, and the “pedal to the floor” tactic does not work at all;

- the power is not felt especially on a hot engine; on a cold engine the behavior practically does not change;

- all problems and malfunctions arise in the vehicle only after the engine has warmed up.

The real problem is that too much or too little air is being supplied, so the power unit cannot cope with the combustion of fuel in normal modes. This leads to the fact that the modes intended by the manufacturer normal operation engines are no longer possible. It is quite difficult for the engine in such situations. If we also take into account the increased consumption, the wear of the power unit also increases.

Also, if air flows incorrectly into the combustion chamber in the engine, incomplete combustion of fuel can be observed. This problem is a serious side effect that can lead to difficult consequences. If unburned gasoline flows into the crankcase, where it mixes with oil, the quality lubricant decreases significantly. This leads to increased friction in the engine and excessive wear of parts.

Checking the MAF sensor yourself - five ways to deal with the problem

If you suspect that the mass air flow sensor is to blame for all your problems, it is worth testing your theory and getting a definite answer to the question. To do this, it is enough to perform diagnostics using one of the methods presented below. But before we talk about methods for checking the sensor, we will give arguments against self-diagnosis and personal servicing of your vehicle.

The technicians at the service station will carry out all the work much faster and without problems, since they have to deal with the mass air flow sensor almost every day. If you make your own efforts to resolve the problem, you are experimenting with the machine at your own risk. However, this troubleshooting option is much cheaper and does not require a trip to the station Maintenance. The main ways to check for problems with the mass air flow sensor are as follows:

- Disconnect the sensor from the air supply system. In this case, the computer gives the command to calculate the amount of air based on the position of the damper in the engine. If, after disconnecting the sensor, the car began to drive better, but increased speed, there is a breakdown of the mass air flow sensor.

- Reinstalling firmware during sensor diagnostics. This method allows you to make sure that engine problems are not associated with alternative ECU firmware, which may well be the original cause of all your problems.

- Checking the mass air flow sensor using a measuring device called Multimer. Only some Bosch sensors can be checked in this way. More details about checking can be found in the instructions for the car or directly to the installed sensor.

- Study and visual assessment sensor status. This traditional testing system can often determine if there is a problem. If inner part The mass air flow sensor is dusty, you can safely change it and carefully monitor the position of all sealing rubber bands.

- Replacing the MAF sensor. This method is suitable for you if you do not want to perform diagnostics, and you have a new sensor in stock. You can simply replace this element and make sure that the problem was hidden in this particular unit.

These simple methods for diagnosing a mass fuel flow sensor will help you determine the most important points operation of this node. Of course, in garage conditions The easiest way is to perform the first and last diagnostic and repair options. These are the most accurate and error-free ways to determine the correct operation of the sensors and adjust the necessary engine operating modes in your car without large financial costs.

However, it is better to diagnose any sensor failures using special equipment. Experts know the immediate indicators bad work this or that sensor, this or that node. They often don't even have to start diagnosing to solve the problem. Despite the description of methods for independently determining all possible problems, we do not recommend your own intervention in the sensor operation system. We suggest watching the video for another way to check with visual support:

Let's sum it up

A successful solution to almost any problem with a car is a trip to a professional service station, professional diagnostics and replacement of spare parts with original ones or those recommended by the manufacturer. But this is not always the case. Sometimes it is much easier and cheaper to carry out personal diagnostics of a car using fairly simple and well-known methods that do not require special equipment.

If you want to try such methods, you can do a DIY test of the mass fuel flow sensor. The only drawback This process is that inept installation of the sensor is almost guaranteed to cause it to fail in the next few months. Therefore, before installation, read the corresponding chapter in the instructions for the car, and also pay attention to the required location of all sealing rubber bands on the device. Have you ever had to change the MAF sensor yourself?

Mass air flow sensor or maf sensor - what is it? Correct name sensor - Mass Airflow sensor, in our country it is often called a flow meter. Its function is to measure the volume of air entering the engine per unit of time.

Principle of operation

The sensor consists of platinum filaments (which is why it is not cheap), through which an electric current is passed, heating them. One thread is the control thread, air passes through the second, cooling it. The sensor produces a pulse-frequency signal, the frequency of which is directly proportional to the amount of air passing through the sensor. The controller records changes in the current passing through the second, cooled filament and calculates the amount of air entering the engine. Depending on the signal frequency, the controller sets the operating duration fuel injectors, adjusting the ratio of air and fuel in the fuel mixture. The readings of the mass air flow sensor are the main parameter by which the controller sets fuel consumption and ignition timing. The operation of the flow meter affects not only the overall fuel consumption, mixture quality, engine dynamics, but also, indirectly, the engine life.

What happens if you turn off the mass air flow sensor?

Let's start with the fact that when the flow meter is turned off, the engine goes into emergency operation mode. What could this lead to? Depending on the car model and, accordingly, the firmware - to stop the engine (as on Toyota) to increased consumption fuel or... no use. Judging by numerous messages from auto forums, experimenters note increased agility after shutdown and the absence of failures in engine operation. No one has carried out careful measurements of changes in fuel consumption and engine life. Whether it is worth trying such manipulations on your car is up to the owner to decide.

Signs of malfunction

A malfunction of the mass air flow sensor can be indirectly judged by the following symptoms:

- The CHEK ENGINE lamp comes on;

- The car accelerates slowly (stumbles);

- Unstable engine operation at idle;

- The engine does not start well when hot;

- Increased fuel consumption;

- The engine stalls while driving when changing gears.

Dirty DMRV (side view)

The symptoms described above can be caused by other reasons, so it is better to accurately check the mass air flow sensor at a service station using specialized equipment. If you don’t have time, don’t want to, or are sorry for the money, you can check the performance of the mass air flow sensor yourself with high, but not 100% reliability.

![]()

Dirty DMRV (top view)

Diagnostics of mass air flow sensor

Difficulties in self-diagnosis of a flow meter are caused by the fact that it is a capricious device. Taking readings at the number of revolutions specified in the manual often does not give results. The readings are normal, but the sensor is faulty. Here are several ways to diagnose the performance of the sensor:

- The easiest way is to replace the mass air flow sensor with a similar one and evaluate the result.

- Check without replacement. Disconnect the flow meter. Unplug the sensor connector and start the engine. When the DMVR is disabled, the controller operates in emergency mode. The amount of fuel for the mixture is determined only by the throttle position. At the same time, the engine keeps speed above 1500 rpm. If during a test drive the car becomes “faster”, then most likely the sensor is faulty

- Visual inspection of the mass air flow sensor. Remove the corrugated air intake tube. First, carefully inspect the corrugation. The sensor may be working properly, but the reason for its unstable operation is cracks in the corrugated hose. If the surface is intact, continue the inspection. The elements (platinum threads) and the inner surface of the corrugation must be dry, without traces of oil and dirt. The most likely cause of the malfunction is contamination of the flow meter elements.

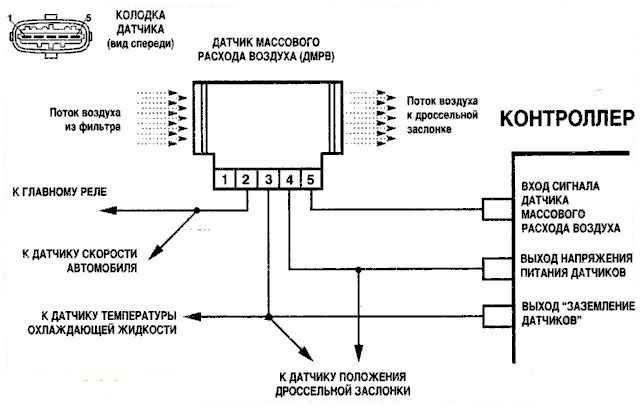

- Checking the mass air flow sensor with a multimeter. The method is applicable for Bosh mass air flow sensor with catalog numbers 0 280 218 004, 0 280 218 037, 0 280 218 116. We switch the tester to measure DC voltage, with a measurement limit of 2 Volts.

Location from closest to windshield in order 1. sensor signal input 2. mass flow sensor supply voltage output 3. grounding (ground). 4. output to the main relay. The color of the wires may vary, but the pin locations are always the same. Turn on the ignition without starting the engine. We connect the red probe of the multimeter through the rubber seals of the connector to the first contact (usually yellow wires), and the black probe to the third one for ground (usually the green wire). We look at the multimeter readings. A new sensor typically reads between 0.996 and 1.01 Volts. Over time, tension usually increases. A higher value corresponds to more wear sensor 1.01…1.02 – sensor is working. 1.02…1.03 – the condition is not the best, but working 1.03…1.04 – the resource is at its limit. 1.04...1.05 - agony 1.05...and more - definitely, it's time to change.

All of the home diagnostic methods described above do not provide a 100% guarantee of the reliability of the result. A reliable diagnosis can only be made using special equipment.

Do-it-yourself prevention and repair of mass flow sensors

You can extend the life of the mass air flow sensor timely replacement air filter and monitoring the condition of piston rings and seals. Their wear causes excess saturation crankcase gases oil An oil film getting on the sensitive elements of the sensor kills it. On a sensor that is still alive, lost readings can be restored by the “Max air flow sensor corrector” program. With its help, you can quickly change the mass air flow sensor calibrations in the firmware. The program is easy to find and download without problems on the Internet. The luftmassensensor reiniger MAF cleaner can help revive a non-working sensor.. To do this you need:

- Remove the sensor from the engine as described above.

- Spray the product thoroughly and generously onto the sensitive element.

- Wait until any remaining dirt has drained away.

- Dry the sensor well before installation. For prevention, the procedure can be repeated before each air filter replacement.

MAF Toyota 22204-22010

If cleaning does not produce results, the faulty sensor must be replaced. The cost of a mass air flow sensor starts from 2000 rubles, and for imported models it is usually significantly higher, for example the price of a Toyota 22204-22010 sensor is about 3000 rubles. If the sensor is expensive, do not rush to buy a new one. Often products of the same marking are installed on different brands cars, but the price of spare parts varies. This story is often observed with Bosh mass air flow sensor. The company supplies the same sensors for VAZ and for many imported models. You need to disassemble the sensor, write down the markings of the most sensitive element, it is quite possible that it can be replaced with a VAZ one.

DBP instead of MAF

IN imported cars, since the 2000s, a pressure detector (DBP) has been installed instead of a flow meter. The advantages of DBP are high performance, reliability and unpretentiousness. But installing instead of a mass air flow sensor is more a matter for those who are keen on tuning than for ordinary car enthusiasts.

How to pay TWICE LESS for GASOLINE

- Gasoline prices are rising every day, and the car's appetite is only increasing.

- You would be happy to cut costs, but is it possible to live without a car these days!?

A mass air flow sensor is required for efficient work engine in different modes. The function of this device is to create a working mixture of air and gasoline vapor. The task of the VAZ 2114 air flow sensor is to measure two interrelated indicators:

- Amount of air consumed;

- Reaction time.

The accuracy of measuring the air consumption of the engine allows the controller to determine in what proportion it is necessary to mix air with fuel. If the sensor produces incorrect values, the resulting air-fuel mixture does not correspond to the current engine operating mode. This leads to a decrease in power, an increase in fuel consumption, and a deterioration in the dynamics and response of the car.

Controller response different manufacturers these parameters may differ.

For example, January-5.1, in case of slight overestimation or underestimation of values, determines the error of the mass air flow sensor based on the readings of the oxygen sensor, thus adjusting the duration of fuel injection. Increasing the sensor response time will cause the controller to not keep up, and at the time of acceleration you will notice “dips” of the engine. The same sensor error when using a more sensitive Bosch controller will lead to floating idle speed, although there will be no noticeable dips during acceleration.

A 1.5 liter VAZ 2114 engine with a working mass air flow sensor at 850-950 rpm consumes from 10±0.5 kg of air per hour of operation, and at 2000 rpm - from 19 kg to 21 kg. If the amount of air consumed at the same speed decreases, the dynamics of the car also decreases, but fuel is saved. Conversely, increased air consumption leads to increased dynamics and higher fuel consumption. In this case, it may be difficult to start the engine. cold weather. If the sensor readings deviate from the real ones by 2-4 kg, the engine will begin to become very capricious and “dull”. Disabling the sensor will force the motor to continue operating in emergency mode.

Causes of malfunction

Common to the majority domestic cars The reason why the VAZ 2114 air flow sensor breaks is hidden in the crankcase ventilation system. It has two circuits that ensure operation with the throttle valve open or closed. If the throttle is buried, crankcase gases are discharged along the line (d=1.5 mm) into the space available behind it. A certain percentage of these gases accumulates in the idle line, where it comes into contact with the film-coated MAF resistor. It is also sensitive to fluctuations in the gas mixture in the intake system. The resin settles on the surface of the resistor, and the sensor begins to “lie.” Because of this, the idle air control sticks, and it begins to jam when starting the engine.

Signs of malfunction

A non-working VAZ 2114 mass air flow sensor leads to the appearance of a number of symptoms in the behavior of the injection engine. The malfunction appears gradually, starting with an increase in fuel consumption and floating speed, ultimately destabilizing engine operation.

From personal experience using an example front wheel drive car, I can say that I encountered the following problem: first the injector icon came on, then the speed began to fluctuate greatly and fuel consumption almost doubled.

You can calculate a non-working VAZ 2114 air sensor using the following criteria:

- failures when idling and under load;

- The internal combustion engine stalls when trying to change gear;

- decreased dynamics, the car accelerates slowly;

- fuel consumption increased;

- engine power has dropped;

- hard to start “hot”;

- The Check Engine light appears.

If the mass air flow sensor is already dead, the Check Engine light may not come on. Then the malfunction can be determined by the error displayed on-board computer. Diagnostics of the MAF signal level will also help. Low level may indicate the following:

- There is no MAF connection;

- malfunction in the sensor connection circuit (break);

- the ground in the connection circuit is broken or oxidized;

- the signal wires are broken or incorrectly connected, perhaps they are short-circuited;

- engine control unit malfunction;

- DMRV does not work.

If you notice the above signs, do not rush to buy a new sensor. It is by no means the cheapest and will cost 1500-4000 rubles. First of all, make sure that this is the reason. You can check and clean the old one at a service center or yourself if you have the necessary equipment.

Checking the mass air flow sensor

Before you start experimenting, take the time to read the manual service. It describes in detail what a mass air flow sensor on a VAZ 2114 is and how to replace it.

We are looking for a sensor. Open the hood and find the air filter pipe. The mass air flow sensor is located on it, which determines the flow of air passing through the filter. I will give several options on how to check the mass air flow sensor yourself.

- Disable the sensor. Disconnect the block with wires from the connector by pressing the latch located below. Start the engine (1500 rpm or more). The controller understands the shutdown of the mass air flow sensor as an emergency condition and prepares the fuel-air mixture based on the position of the throttle valve. Try driving a short distance. If the car accelerates noticeably faster, this indicates a non-working mass air flow sensor. I would like to note that in the disabled state for ECUs Y7.2 and M7.9.7. RPM doesn't increase!

- Replacing the controller firmware. The original ECU firmware could have been replaced with an alternative one. In such a situation, we do not know which algorithm is prescribed in the case of operation in the mode discussed in the first paragraph. The throttle valve has a stop under which you need to place a thin plate (about 1 mm) to raise the speed. Then you need to disconnect the chip with the sensor. At faulty sensor the engine should stall. If the engine is running, then the reason is due to the firmware features: the IAC steps are written incorrectly.

- Voltage measurement. Testing gives good results when working with Bosch sensors. You will need a multimeter. Select the DC voltage measurement mode and set maximum value 2 V.

The connection diagram for the VAZ 2114 looks like this:

- yellow – incoming signal;

- gray with white – power output;

- green – grounding;

- pink with black – output to the main relay.

The colors may be different, but the sequence of connectors is the same.

Next, you need to turn on the ignition with the engine off. Connect the red (positive) probe of the tester to the yellow output, and the black (negative) probe to the green. Multimeter probes are inserted along the specified wires directly through the rubber seals of the connectors without damaging the insulation. For prevention, I recommend moistening the probes with WD-40. Intermediates or needles are not recommended due to the additional error they introduce. Measure the voltage. Compare the result with the table:

A newly installed sensor gives an output voltage of 0.996–1.01 V. Over time, it increases. A higher value means a higher percentage of wear.

Voltage data from the sensors is recorded by the on-board computer and can be viewed by selecting the appropriate group of parameters.

- Inspection and cleaning.

- Use a Phillips screwdriver to loosen the clamp holding the air intake pipe. We remove the corrugation and check whether there are traces of oil and/or condensation inside it, as well as on the inner surface of the sensor. Normally they shouldn't be there. The sensing element of the mass flow sensor often breaks due to dirt getting on it. This can easily be avoided by regularly replacing the air filter. Reasons for oil getting into the air flow sensor:

- the permissible oil level in the crankcase has been exceeded

The oil separator of the ventilation system is clogged

- The sensor is attached to the pipe with two screws. We unscrew them with an open-end wrench (x10) and remove the sensor itself. There is an entrance at the front, which must be protected from the leakage of untreated air with an o-ring rubber seal. If it is missing or remains in the filter housing, dust clogs the sensor input grid. It needs to be cleaned, the seal installed, the leaks checked and the sensor put back in. Comparison with a working sensor. On personal experience

I was convinced that the most accurate test is to install a known working sensor and compare the behavior of the engine with the “native” one.

In addition to the options considered for how to check the mass air flow sensor yourself, you can also contact a service center that has special equipment and carry out 100% diagnostics, for example, using the method of evaluating an oscillogram. This article will discuss the purpose, device and diagnostics mass air flow sensor (MAF) , which is an integral part injection engines . Many modern owners periodically encounter problems associated with unstable work

injection In most cases, this problem lies in a malfunction of the mass air flow sensor (MAF).

Mass air flow sensor – small device, is installed on the pipe that connects the air filter and throttle valve and serves to control the amount of air entering the VAZ engine.

Two platinum filaments are installed in the mass flow sensor housing, which heat up under the influence of electric current. When air passes through the sensor, it cools the first thread, the current resistance changes accordingly, the second thread is the control. Thus, the amount of air entering the injection engine is estimated. Received data from mass air flow sensor enter the electronic control unit () where the required ratio of air and fuel is calculated for subsequent supply to the combustion chambers of the engine cylinders.

Signs of malfunctions caused by a breakdown of the air flow sensor on VAZ cars.

If it fails, then you will most likely see a light on on the instrument panel. Check indicator Engine. At the same time, you will feel how the car has lost its dynamics, increased performance has appeared and it has become more difficult to start a hot engine.

Diagnostics of the mass air flow sensor

There are several ways to check the mass air flow sensor on injection engines of VAZ cars.

Option #1. Disabling the mass air flow sensor

This option DMRV diagnostics is the simplest, and every car owner can do it. First you need to disconnect the mass air flow sensor; to do this, disconnect the connector and start the engine. After this, the controller goes into emergency mode, and the supply of the fuel mixture is adjusted only with the help of the throttle valve, while the idle speed exceeds the reading of 1500 rpm. Now we get behind the wheel of the car and do a test drive. If you feel that the car has increased in , then you can conclude that mass air flow sensor out of order.

Option #2. Diagnosing the mass air flow sensor using a multimeter

Before we begin describing this method of diagnosing the mass air flow sensor, we note that this procedure is only relevant for Bosch sensors with catalog numbers: 0 280 218 004, 0 280 218 037, 0 280 218 116.

Before checking, you must set the measurement limit on the multimeter to 2 Volts and switch it to operating mode with constant voltage. Next, look at the table that shows the pinout MAF connector.

- Mass air flow sensor signal input. The yellow wire is located on the edge towards the windshield.

- Sensor supply voltage output. Gray-white wire

- Output grounding sensors. Green wire

- There is a pink and black wire going to the main relay.

Please note that the colors of the wires in some cases may differ from the examples given, but the location of the contacts on the MAF connector always remains the same.

We connect the red contact of the multimeter to the yellow wire on the connector, and the black one to the green (to ground), while the engine should not be running. At this stage we measure the voltage between the specified pins.

The measuring contacts of the multimeter have needle tips, which allow measurements to be taken through the protective seals without disturbing their insulation.

Multimeter reading during DMRV diagnosis.

Option #3. External signs of a malfunction of the mass air flow sensor

To visually assess the serviceability or malfunction of the mass air flow sensor on a VAZ car engine, you need to carefully inspect the internal surfaces of the air pipe on which the mass air flow sensor is installed. To do this, use a shaped screwdriver to unscrew the screw, loosen the clamp and disconnect the corrugation. Its internal surface, as well as the surface of the sensor itself, must be dry and free of oil deposits.

Note that one of reasons for failure of the air flow sensor is the ingress of dirt onto its working surface due to untimely replacement air filter. And the presence of oil deposits indicates an increased oil level in the engine, or a malfunction of the oil cut-off valve and the crankcase ventilation system.

The next stage of visual diagnostics of the mass air flow sensor There will be a complete removal and inspection. To remove Mass air flow sensor You need to use a 10mm wrench to unscrew the two screws and remove it from the air filter housing. Along with the sensor, a rubber sealing ring should also come out, which prevents air leaks. If it remains in the housing, then most likely this will be one of the reasons that led to the breakdown of the sensor. Due to a violation of the seal between the filter housing and the sensor, a deposit of dust forms on the inlet grid of the mass air flow sensor, and this is not acceptable.

Correct installation of the mass air flow sensor prevents the rubber seal from becoming distorted.

The procedure for assembling and installing the mass air flow sensor

In conclusion, I would like to note that all of the above ways to check the mass air flow sensor are not entirely accurate. A complete diagnosis of the mass air flow sensor can only be carried out with special equipment that will take readings at various engine operating modes.